is is a great gift idea for those metal workers out there that would like to make something for a friend who does not have a need for a steam engines, dial indicator holder, or a brass hammer.

I live in Texas where playing Dominos in the back of the feed store is quite popular. I made several sets and packaged them in nice wooden boxes for Christmas presents a few years back.

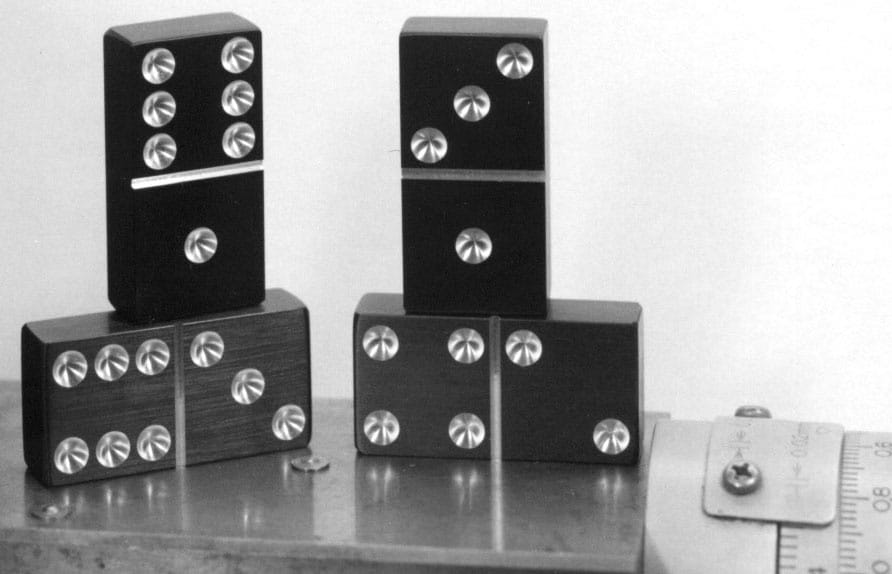

This shows a few of the dominos sitting on the compound of my lathe. They are made of 6061-T651 Aluminum Alloy. Do not use 2024 or 7075, they do not anodize very well. I purchased the material in 1 / 2 by 1″ bar stock. The Domino blanks were sawed 2″ long on a table saw with a cut-off box. My saw did a good job, and it was not necessary to clean-up the ends on the mill. A little WD-40 helps the saw do it’s job without clogging. A twelve foot bar will make two sets plus spares.

Next, edges of the blanks are softened on the belt sander. Ends are dressed and grained, as well as the sides. Again, a little WD-40 on the sanding belt prevents the belt from “burning” the aluminum. The blanks should be nice and shiny with smooth even graining.

Wrap the blanks up carefully to prevent scratching and take them to an anodizer. Anodizing is generally not the sort of thing you would want to do at home. Tell the anodizer what you are up to. The shop I went to anodized eight sets for free, after I told him I would give him one of the finished sets. Black is the best color, but almost any color is available. Once the blanks are anodized, cut the line across the middle using a slitting saw or other suitable cutter. I used a gear cutter because it left the groove with a small radius at the bottom. A narrow kerf blade in the table saw would work well.

This shows a few of the dominos sitting on the compound of my lathe. They are made of 6061-T651 Aluminum Alloy. Do not use 2024 or 7075, they do not anodize very well. I purchased the material in 1 / 2 by 1″ bar stock. The Domino blanks were sawed 2″ long on a table saw with a cut-off box. My saw did a good job, and it was not necessary to clean-up the ends on the mill. A little WD-40 helps the saw do it’s job without clogging. A twelve foot bar will make two sets plus spares.

Next, edges of the blanks are softened on the belt sander. Ends are dressed and grained, as well as the sides. Again, a little WD-40 on the sanding belt prevents the belt from “burning” the aluminum. The blanks should be nice and shiny with smooth even graining.

Wrap the blanks up carefully to prevent scratching and take them to an anodizer. Anodizing is generally not the sort of thing you would want to do at home. Tell the anodizer what you are up to. The shop I went to anodized eight sets for free, after I told him I would give him one of the finished sets. Black is the best color, but almost any color is available. Once the blanks are anodized, cut the line across the middle using a slitting saw or other suitable cutter. I used a gear cutter because it left the groove with a small radius at the bottom. A narrow kerf blade in the table saw would work well.

The jig for cutting the dots is shown in the second photo. This jig is not necessary, but it makes the production of multiple sets much easier and error free.

Two type 601 De-Sta-Co clamps are used to hold the Domino blank against the delrin stops. Note the use of nylon screws as bumpers in the clamps. The fourteen holes drilled in the fixture are used to index the fourteen possible dot locations on the top of the Domino. It is necessary to load the Domino blank into the fixture just one time, making it less likely for the Domino to get scratched during production. To use the fixture, a plate, with a pin that fits the holes in the jig, is clamped in the milling machine or drill press. The index pin is carefully lined-up with the machine spindle. The dots are cut with a .250″ diameter ball end mill to a depth of .100″. See photo 3. It is a good idea to use a lubricant such as Tapmatic for Aluminum. This will help produce a bright dot and lesson the chance of producing a burr.

Wash the Dominos in dish washing soap and dry thoroughly. It is a good idea to treat the finished Dominos to a light coat of wax. To do this, thin a small amount of paste wax with mineral spirits. Apply liberally and wipe off excess. After the wax has dried, buff the Dominos with a soft cloth.

A beautiful set of Dominos such as these need to be kept in a nice container. For the sets I gave as gifts, I made boxes from Teak with an inlaid figure in the lid. The inlay? The silhouette of the state of Texas.

The jig for cutting the dots is shown in the second photo. This jig is not necessary, but it makes the production of multiple sets much easier and error free.

Two type 601 De-Sta-Co clamps are used to hold the Domino blank against the delrin stops. Note the use of nylon screws as bumpers in the clamps. The fourteen holes drilled in the fixture are used to index the fourteen possible dot locations on the top of the Domino. It is necessary to load the Domino blank into the fixture just one time, making it less likely for the Domino to get scratched during production. To use the fixture, a plate, with a pin that fits the holes in the jig, is clamped in the milling machine or drill press. The index pin is carefully lined-up with the machine spindle. The dots are cut with a .250″ diameter ball end mill to a depth of .100″. See photo 3. It is a good idea to use a lubricant such as Tapmatic for Aluminum. This will help produce a bright dot and lesson the chance of producing a burr.

Wash the Dominos in dish washing soap and dry thoroughly. It is a good idea to treat the finished Dominos to a light coat of wax. To do this, thin a small amount of paste wax with mineral spirits. Apply liberally and wipe off excess. After the wax has dried, buff the Dominos with a soft cloth.

A beautiful set of Dominos such as these need to be kept in a nice container. For the sets I gave as gifts, I made boxes from Teak with an inlaid figure in the lid. The inlay? The silhouette of the state of Texas.

This shows a few of the dominos sitting on the compound of my lathe. They are made of 6061-T651 Aluminum Alloy. Do not use 2024 or 7075, they do not anodize very well. I purchased the material in 1 / 2 by 1″ bar stock. The Domino blanks were sawed 2″ long on a table saw with a cut-off box. My saw did a good job, and it was not necessary to clean-up the ends on the mill. A little WD-40 helps the saw do it’s job without clogging. A twelve foot bar will make two sets plus spares.

Next, edges of the blanks are softened on the belt sander. Ends are dressed and grained, as well as the sides. Again, a little WD-40 on the sanding belt prevents the belt from “burning” the aluminum. The blanks should be nice and shiny with smooth even graining.

Wrap the blanks up carefully to prevent scratching and take them to an anodizer. Anodizing is generally not the sort of thing you would want to do at home. Tell the anodizer what you are up to. The shop I went to anodized eight sets for free, after I told him I would give him one of the finished sets. Black is the best color, but almost any color is available. Once the blanks are anodized, cut the line across the middle using a slitting saw or other suitable cutter. I used a gear cutter because it left the groove with a small radius at the bottom. A narrow kerf blade in the table saw would work well.

This shows a few of the dominos sitting on the compound of my lathe. They are made of 6061-T651 Aluminum Alloy. Do not use 2024 or 7075, they do not anodize very well. I purchased the material in 1 / 2 by 1″ bar stock. The Domino blanks were sawed 2″ long on a table saw with a cut-off box. My saw did a good job, and it was not necessary to clean-up the ends on the mill. A little WD-40 helps the saw do it’s job without clogging. A twelve foot bar will make two sets plus spares.

Next, edges of the blanks are softened on the belt sander. Ends are dressed and grained, as well as the sides. Again, a little WD-40 on the sanding belt prevents the belt from “burning” the aluminum. The blanks should be nice and shiny with smooth even graining.

Wrap the blanks up carefully to prevent scratching and take them to an anodizer. Anodizing is generally not the sort of thing you would want to do at home. Tell the anodizer what you are up to. The shop I went to anodized eight sets for free, after I told him I would give him one of the finished sets. Black is the best color, but almost any color is available. Once the blanks are anodized, cut the line across the middle using a slitting saw or other suitable cutter. I used a gear cutter because it left the groove with a small radius at the bottom. A narrow kerf blade in the table saw would work well.

The jig for cutting the dots is shown in the second photo. This jig is not necessary, but it makes the production of multiple sets much easier and error free.

Two type 601 De-Sta-Co clamps are used to hold the Domino blank against the delrin stops. Note the use of nylon screws as bumpers in the clamps. The fourteen holes drilled in the fixture are used to index the fourteen possible dot locations on the top of the Domino. It is necessary to load the Domino blank into the fixture just one time, making it less likely for the Domino to get scratched during production. To use the fixture, a plate, with a pin that fits the holes in the jig, is clamped in the milling machine or drill press. The index pin is carefully lined-up with the machine spindle. The dots are cut with a .250″ diameter ball end mill to a depth of .100″. See photo 3. It is a good idea to use a lubricant such as Tapmatic for Aluminum. This will help produce a bright dot and lesson the chance of producing a burr.

Wash the Dominos in dish washing soap and dry thoroughly. It is a good idea to treat the finished Dominos to a light coat of wax. To do this, thin a small amount of paste wax with mineral spirits. Apply liberally and wipe off excess. After the wax has dried, buff the Dominos with a soft cloth.

A beautiful set of Dominos such as these need to be kept in a nice container. For the sets I gave as gifts, I made boxes from Teak with an inlaid figure in the lid. The inlay? The silhouette of the state of Texas.

The jig for cutting the dots is shown in the second photo. This jig is not necessary, but it makes the production of multiple sets much easier and error free.

Two type 601 De-Sta-Co clamps are used to hold the Domino blank against the delrin stops. Note the use of nylon screws as bumpers in the clamps. The fourteen holes drilled in the fixture are used to index the fourteen possible dot locations on the top of the Domino. It is necessary to load the Domino blank into the fixture just one time, making it less likely for the Domino to get scratched during production. To use the fixture, a plate, with a pin that fits the holes in the jig, is clamped in the milling machine or drill press. The index pin is carefully lined-up with the machine spindle. The dots are cut with a .250″ diameter ball end mill to a depth of .100″. See photo 3. It is a good idea to use a lubricant such as Tapmatic for Aluminum. This will help produce a bright dot and lesson the chance of producing a burr.

Wash the Dominos in dish washing soap and dry thoroughly. It is a good idea to treat the finished Dominos to a light coat of wax. To do this, thin a small amount of paste wax with mineral spirits. Apply liberally and wipe off excess. After the wax has dried, buff the Dominos with a soft cloth.

A beautiful set of Dominos such as these need to be kept in a nice container. For the sets I gave as gifts, I made boxes from Teak with an inlaid figure in the lid. The inlay? The silhouette of the state of Texas.