Category: Metal Removal

-

Rockwell/Delta Lathe Backgear Repair

Background Most modern lathes incorporate a secondary gear reduction into their design to allow the user to select the speed required for part being machined. In some designs like those from South Bend and Myford, the reducing gear is located under the headstock cover on the rear of the lathe – thus the name “backgear”.…

-

The Gingery Band Saw

One of the most useful shop items is the cutoff bandsaw. The imports, selling for about $200, are common, but many owners complain of their poor quality. Now you can make your own bandsaw that’s bigger, more accurate, and you can probably build it for less than the import version. Dave Gingery, known for his…

-

Mike Sosna’s 1.8X Gingery Mill

My friend Mike Sosna from Stoughton, Saskatchewan in Canada, displayed this Gingery milling machine at the Estevan Model Engineering Show in October 1999. Here are some photos and notes he sent to me recently. Mike is not on the internet. Mill Specifications Head Size Inside – #3 Morse Taper Outside – 1.85″ x 8tpi Nose – 1º”…

-

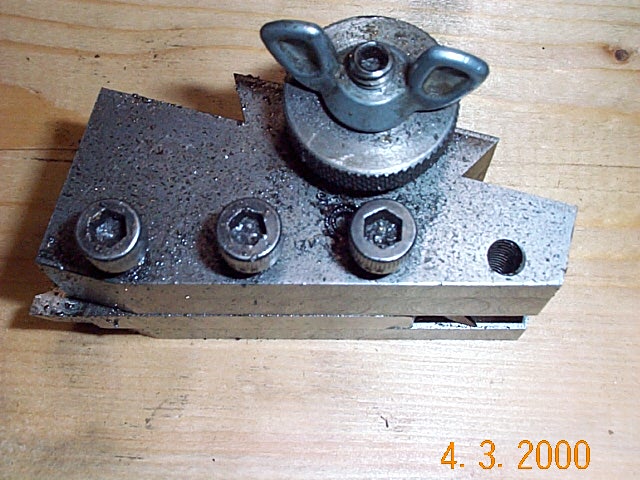

Making a Fixture for Carbide Insert Tool Holder

Here is a fixture I made to mill the toolholders for TNMP inserts described by E. M. (Ted) Edwards. (See: Ted Edwards) With no rotary table or mill, I made it all on the lathe and drill press. The fixture consists of 3 pieces: 1) a Clamp Rail by which to mount it in your toolpost;…

-

Making a Tool Holder for Carbide Inserts

I have a Smithy 3 in 1 lathe/mill/drill so this article is oriented toward relatively light machines. No 1/4″ cuts off old steel axles. Mind you, I do take 30 to 40 thou roughing cuts on mild steel. My machine came with a square block toolholder that can accomodate up to four cutters of up to…

-

Building a Quick Change Tool Holder Knurl

QUICK CHANGE TOOL HOLDER – KNURL The above knurl is designed to fit into a quick change tool holder block. The tightner (upper left), the handle is 1/4″ steel rod about 3 inches long. The handle hub is 3/4″ dia. brass rod and should be tall enough to allow the handle to clear the height…

-

A Novice Builds A Toolpost

Introduction I’ve recently completed my version of the toolpost described in Instructions for making a Quick Change Tool Post. I think this is an excellent project for beginners like myself: Often we have stretched our budgets just to aacquirethe basic machinery, and have limited funds available for “jewelry”. The toolpost will require a fair number of…

-

Instructions for Making an Adjustable Back Plate

The plate is radially adjustable to allow exact centering of any object mounted on the plate. First one gets the object centered within a few tens of thousandths of an inch and then centers it by adjusting the four bolts until the object runs true; just like a 4-jaw chuck. There are a few secrets…

-

Instructions for making a Quick Change Tool Post

A Quick Change Toolpost In production engineering anything that can save time or an operation also saves money. In model engineering it does not apply as rigidly but where it can be applied it can pay dividends in time. We all use these shortcuts whether we realise it or not. Using one item to drill…

-

Instructions for Making a Lathe Back Plate for a Screw Thread Spindle Nose

LATHE CHUCK MOUNT Some people shy away from making chuck mounts (backing plates) for lathes with a screw-thread spindle nose. I have a theory about backing plates on screw-threaded spindles. Common wisdom claims that it is the smooth cylinder between the spindle thread and the spindle collar that axially aligns the backing plate and therefore the…